Batch Biological Treatment to Remove COD &NH3 from Pharma Effluent

The Effluent from the pharmaceutical industries in Hyderabad is highly toxic.

Summary of the Report in Chemical Week September 5, 2007:

Researchers at Gothenburg University in Sweden, led by Joakim Larsson, have identified pharmaceuticals,

some at levels unprecedented anywhere in the world, in wastewater discharged from pharmaceutical

manufacturing plants near Hyderabad, India. The findings were published on July 6, 2007 online by the

"Journal of Hazardous Materials."

Hyd as home of Bulk Drugs: There are over 20 Large companies in and around Hyderabad. Each company having 7-8 Manufacturing units. Each unit is generating around 100-120 KL of Effluent per day. There are around 300 small companies, each generating around 40 KL of effluent per Day.

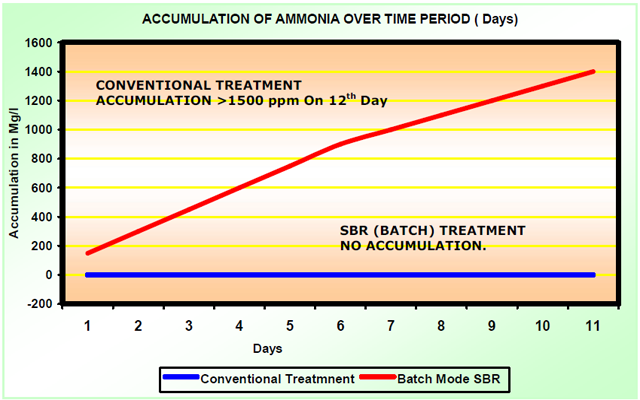

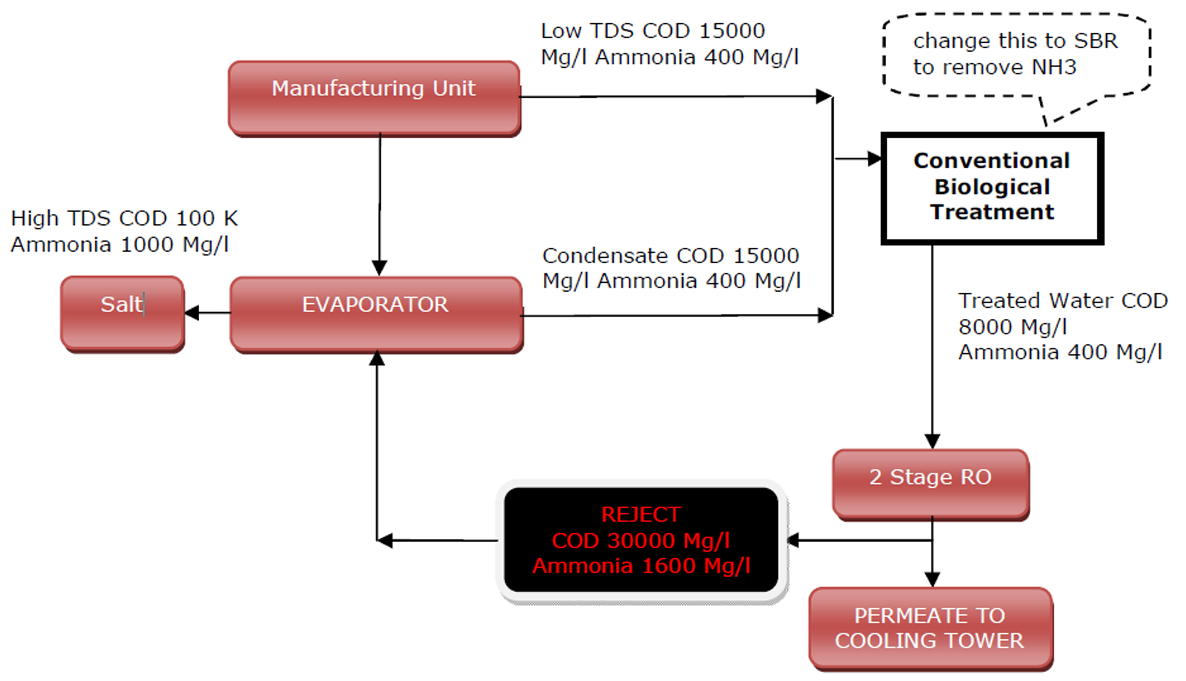

Current status of treating the effluents: All the units has a treatment plant typically comprising of Evaporator, Conventional Biological treatment & a 2 stage RO Plant as described in the flow diagram. The feed to the biological process is Evaporator condensate and low TDS water i.e., COD of 15000 Mg/l & Ammonia 400 Mg/l. Providing a Reverse Osmosis Plant also does not solve the volatile COD and NH3 problem since the Ammonium Salts are rejected by Membrane and the reject when fed to evaporator produces condensate having higher ammonia. This kind of progressive Accumulation of Ammonia is shown in flow chart. Free NH3 in water is very toxic to fish.

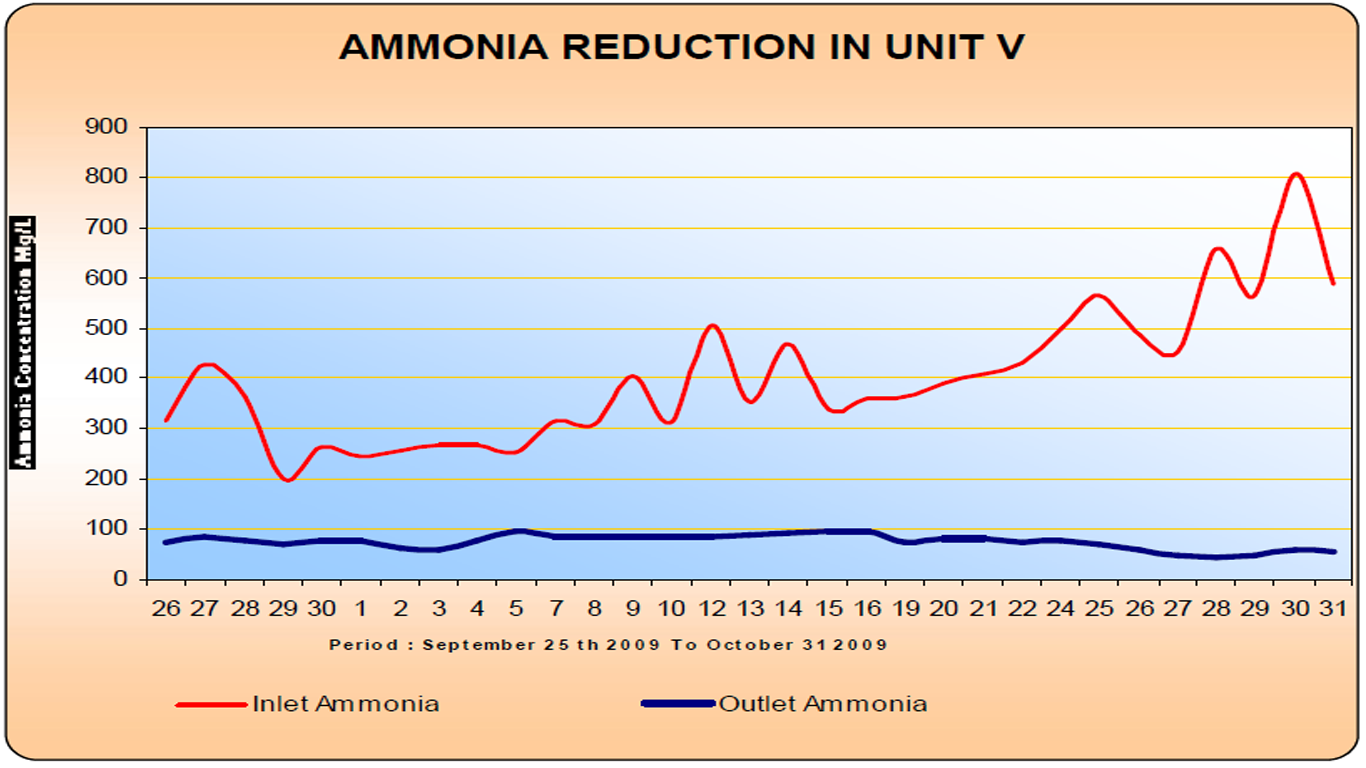

The output treated water using the conventional biological treatment is typically around 8000 mg/L of COD and 350 mg/L of ammonia.

There are about 8 common effluent treatment facilities. However, these facilities receive effluent with a maximum COD of < 5000 Mg/l and Ammonia < 50 Mg/l due to constraints on design and or process. Hyderabad is land locked making it more critical. The mismatch has lead to the findings of the Swedish University. There is an urgent need for a suitable technology to bridge this gap.

Our Innovation:

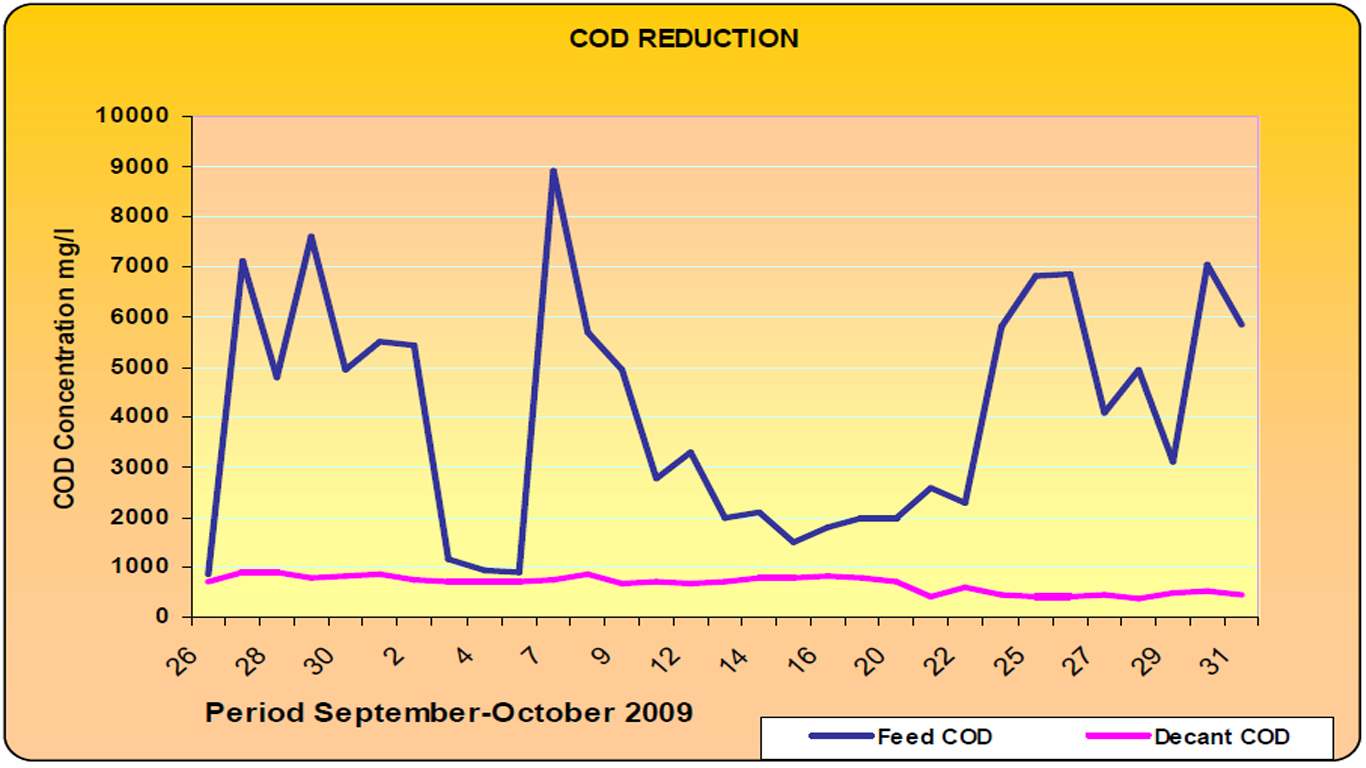

Since many of the chemicals that contribute to COD are not easily degradable, the task is very challenging. There is no technology available to achieve this anywhere in the world. We have worked for more than three years to arrive at a suitable treatment process to effectively reduce the COD to less than 500 Mg/l, i.e., most of the drug intermediates will be removed and Ammonia less than 50 Mg/l.

1. We converted the conventional process to SBR / batch type operation . There is no short

circuiting of the effluent. All the molecules have to reside inside the tank for the same amount of time, say

9 days.

2. Special inoculum was also developed using the latest techniques in micro biology. The health of the

bacteria was monitored on a daily basis.

3. Feed is added daily only after all the criteria have been satisfied using the analytical data.

RO plant has also been installed and the recovery is around 70%. With the second stage RO, this will reach 95%. Being Biological this technology is eco friendly, highly cost effective, robust. The water bodies in Hyderabad will become safer with this technology This technology has been in operation at M/S. MATRIX LABORATORIES LIMITED, HYDERABAD since Feb 2009 and the operational details are as under.